Process Cooling Problems? Here’s What Plastic Factories Are Doing to Fix Them

In the fast-paced world of plastic production, process cooling issues are more than a mere trifle — they can cause significant delays, substandard product quality, and wasted energy. Throughout the UAE, where temperatures soar and industrial demand is high, reliable and efficient cooling systems are essential to achieving operational success. That is where seasoned solution providers like PRESTO step in, providing innovative solutions specifically designed for the process cooling of plastic plants.

Why Cooling Is Important in Plastic Production

Plastic production entails processes such as injection molding, blow molding, and extrusion — all of which are very heat-generating. Unchecked, this heat can damage machinery, warp products, and slow down the production cycle. Effective cooling systems eliminate this heat from the process, keeping operating temperatures at their optimal levels.

In the UAE, where production needs and environmental temperatures are high, process cooling for plastic manufacturing plants is a crucial function in:

- Ensuring product quality and consistency

- Minimizing machine downtime

- Increasing equipment lifespan

- Conserving energy

- Compliance and safety requirements

Yet despite the knowledge of the need for cooling, most factories continue to experience recurring issues.

Process Cooling Issues Experienced by Plastic Factories in the UAE

1. Insufficient Cooling Capacity

Factories often increase their production without upgrading their cooling systems. Consequently, chillers and cooling towers fail to meet the additional load, resulting in non-uniform temperature control and overheating issues.

2. High Energy Consumption

Inefficient or outdated cooling systems consume higher amounts of electricity, which increases the operational cost. In a market like the UAE, where cooling systems must operate more efficiently due to elevated ambient temperatures, this is a significant concern.

3. Water Usage & Treatment Challenges

Water-cooled systems are popular, but they require a reliable water supply and proper treatment to prevent scaling, corrosion, and bacterial growth. Inadequate water or improper treatment raises maintenance requirements and lowers system efficiency.

4. System Breakdowns and Downtime

Sudden breakdowns in chillers, cooling towers, or pumps result in production delays and lower product quality. They are usually the result of inadequate maintenance, obsolescent components, or inefficient system design.

5. Absence of System Integration

Many facilities operate with standalone cooling units that aren’t integrated into the broader production system. This lack of integration can lead to inefficient load sharing, delayed responses to temperature changes, and overall energy wastage.

What Plastic Factories Are Doing to Fix These Cooling Problems

1. Investing in Modern Cooling Systems

Factories are shifting away from traditional cooling techniques and making investments in power-saving systems, such as air-cooled or hybrid chillers, that provide improved temperature regulation and reduced power consumption. Advanced process cooling services for plastic factories are being offered by companies such as PRESTO, which are customized to fulfill individual production requirements.

2. Employing Centralized Cooling Systems

In contrast to the use of several independent, standalone chillers, numerous buildings in the UAE are adopting centralized cooling systems. This not only enhances performance and efficiency but also saves energy and maintenance costs in the long run.

3. Integration of Automation and Control Systems

Automated control systems and sensor-equipped intelligent cooling systems are being used to regulate cooling output in real-time based on actual demand. This results in peak performance, minimized energy consumption, and extended system lifespan.

4. Regular Maintenance & Monitoring

Preventive maintenance is the new watchword. With advanced diagnostic equipment, factories can pick up and repair problems such as refrigerant leaks, fouling, or motor failure before they cause expensive downtime.

5. Changing over to Sustainable Cooling Solutions

Environmental sustainability is gaining prominence. Manufacturers are increasingly using eco-friendly refrigerants and water-conserving technologies. PRESTO, for example, offers solutions that meet international environmental standards while delivering the highest level of performance.

The PRESTO Role in Resolving Process Cooling Issues

PRESTO is a premier solution company in the UAE that delivers customized process cooling solutions to plastic factories. With intimate knowledge of industrial cooling issues in hot environments, PRESTO provides:

- Tailored cooling system design according to your production process, factory floor layout, and cooling requirements

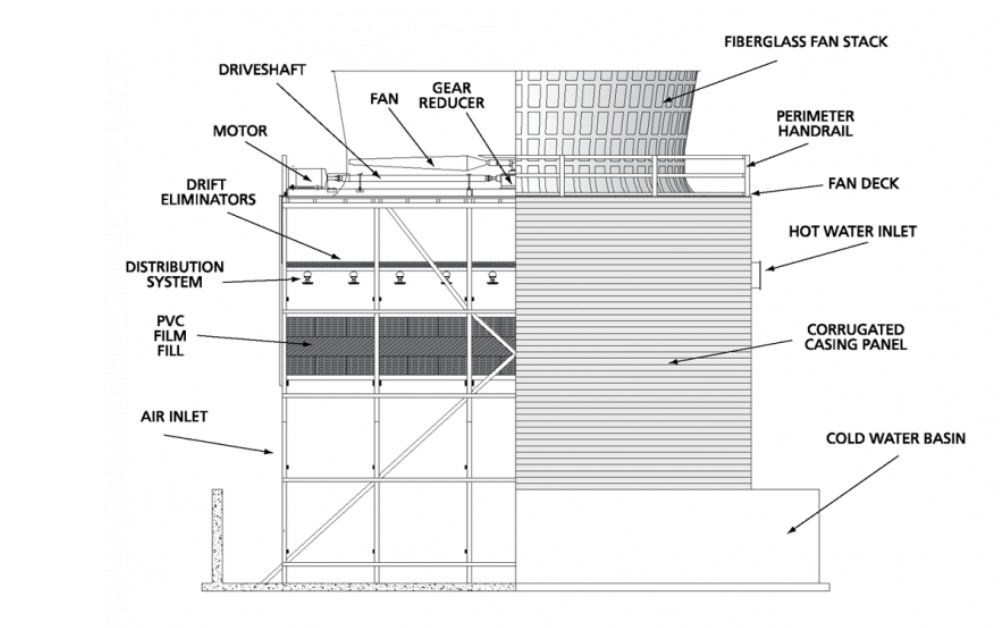

- Efficient chillers and cooling towers designed explicitly for the UAE’s climatic conditions

- Water-conserving and energy-efficient systems that lower operation costs

- 24/7 technical support and maintenance services

- IoT-based monitoring and automation for total control

Whether you have a small molding unit or a large plastic manufacturing plant, PRESTO’s extensive portfolio of cooling solutions guarantees your factory operates smoothly, effectively, and sustainably.

Why UAE Plastic Manufacturers Trust Contemporary Cooling Solutions

The UAE’s plastic production industry is expanding rapidly, driven by an increase in both local and foreign demand. Factories must be competitive, so they require steady production, low business costs, and high-quality products — all of which are highly related to process cooling efficiency.

By adopting advanced cooling methods and collaborating with experienced suppliers such as PRESTO, plastic factories can:

- Meet deadlines for production.

- Enhance product quality

- Meet sustainability goals

- Maintain worker safety and equipment life.

Conclusion

Process cooling issues are a significant roadblock for most plastic producers in the UAE, but they can be overcome. Technological advancements, preventive maintenance, and intelligent integration enable factories today to overcome these hurdles and achieve greater efficiency and profitability.

If your plant is experiencing high energy bills and inconsistent product quality, it’s time to consider replacing your cooling systems. PRESTO, as a specialist in process cooling for plastic factories, provides complete solutions specifically designed for the UAE market.

Contact PRESTO today and initiate the journey towards an improved, more reliable, and future-proof cooling system for your plastic production processes.