Key Cooling Challenges in Plastic Factories — and How to Fix Them

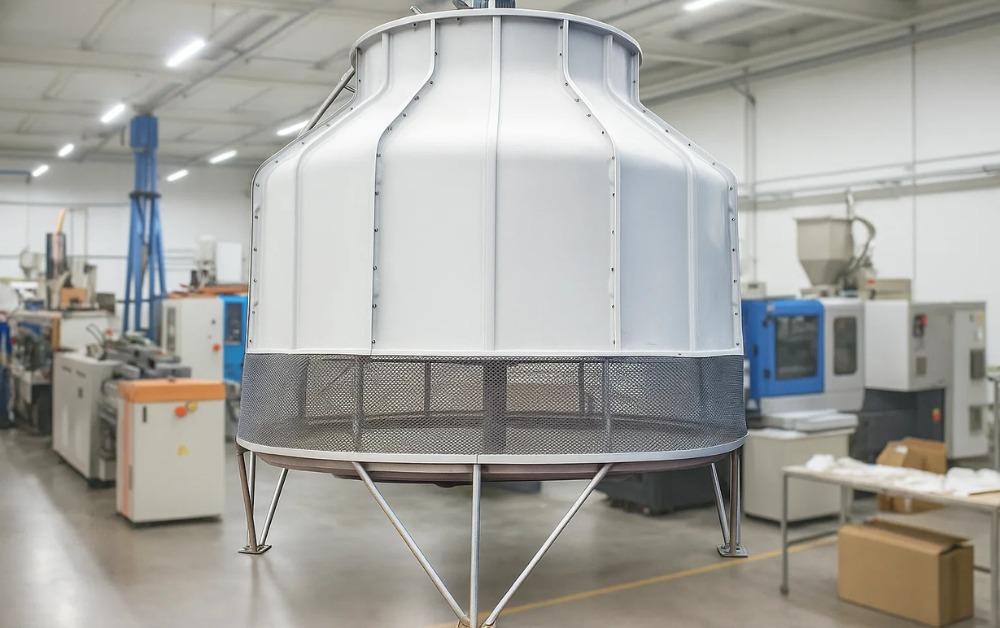

Anyone who’s spent time inside a plastic manufacturing plant knows how intense the heat can get. From extrusion to injection molding, every stage of production generates significant heat that can quickly build up if not adequately controlled. Keeping that heat in check isn’t just about comfort — it’s critical for product quality, equipment life, and overall efficiency.

If cooling systems aren’t doing their job, the consequences show up fast: warped parts, slower production, and machines pushed to their limits. Understanding where the real challenges lie — and how to tackle them — can make all the difference between smooth production and costly downtime.

Why Cooling Matters So Much

Plastic manufacturing runs on precision. The material has to be heated, molded, and cooled at the exact proper temperatures — there’s very little room for error. When the cooling system can’t keep up, the results show up in the final product and the factory’s bottom line.

Effective cooling helps ensure:

- Steady product quality: Prevents warping, shrinkage, and other defects.

- Longer machine life: Keeps molds, motors, and extruders from overheating.

- Better energy use: Reduces strain on HVAC and process systems.

For these reasons, many factories invest in process cooling for plastic factories to maintain operational stability and meet production standards.

The Main Cooling Challenges — and Practical Solutions

1. Managing Extreme Heat Loads

Plastic machines generate enormous amounts of heat, often faster than standard cooling systems can handle. The heat from extruders, molds, and blowers can quickly raise ambient temperatures across the factory floor.

How to fix it:

Use a centralized chiller or modular cooling setup planned for heavy industrial loads. By pulling heat directly from the machines instead of relying on room air, these systems keep temperatures consistent & manageable. Properly sizing and placing the cooling equipment is key — it ensures even performance without overloading any one area.

2. Temperature Swings

Even small temperature shifts can affect how plastic sets. A mold that cools unevenly can lead to warped or brittle products.

How to fix it:

Use cooling circuits that are tightly controlled with sensors and intelligent automation. Precision chillers can maintain consistent temperatures, and regular calibration ensures stability. Adding real-time monitoring helps spot & correct issues before they start affecting production.

3. Poor Water Quality and Scaling

When water’s used for cooling, minerals & impurities can build up inside pipes and chillers, forming scale that reduces heat transfer & strains the system.

How to fix it:

Invest in water treatment and filtration. Keep the system clean with descaling solutions, filters, and softeners where required. Regular checks & maintenance are the simplest, most cost-effective ways to prevent severe damage later.

4. Limited Space

Space constraints are a common headache. Cooling equipment often needs to be close to the machines, but floor space is already packed with production lines.

How to fix it:

Compact or modular chillers work well in tight areas. Placing them strategically near high-heat machines reduces long piping runs & improves efficiency. In many cases, simply redesigning the layout for better airflow can have a noticeable impact.

5. High Energy Costs

Cooling can easily become one of the most significant energy expenses in a factory — especially if the system runs full tilt all day, regardless of demand.

How to fix it:

Switch to energy-efficient chillers and pumps equipped with variable-frequency drives (VFDs). They automatically adjust their output in response to real-time needs, reducing unnecessary power consumption. Intelligent control systems can further optimize cooling based on machine load and outside temperature, resulting in significant savings over time.

6. Hot Weather Performance

In places like the UAE, outdoor temperatures are high enough to strain even the best air-cooled chillers. When the air around the condenser is too warm, the system’s efficiency drops.

How to fix it:

Use water-cooled or hybrid chillers designed for high-temperature climates. Insulate all pipes and storage tanks to reduce heat gain. It’s also wise to create the system with redundancy — an extra cooling loop can keep operations stable even on the hottest days.

7. Maintenance Issues

Cooling systems are easy to overlook when production’s busy — until something fails. Leaks, clogged filters, or worn parts can quietly reduce performance long before a breakdown occurs.

How to fix it:

Stick to a preventive maintenance schedule. Check pumps, valves, & filters regularly, & do not skip cleaning. Use monitoring tools to catch minor issues, like pressure drops or temperature inconsistencies, early. A bit of routine upkeep saves far more time & money than emergency repairs.

8. Integrating New Systems

Adding or upgrading a cooling system in an existing plant can get tricky. If the setup isn’t integrated properly, it can interfere with other systems or waste energy.

How to fix it:

Start with a thorough assessment. Map out heat sources, existing utilities, and airflow paths before installation. Modular cooling systems are often easier to fit into existing spaces and can be expanded later as production grows.

Related read:-Process Cooling Problems? Here’s What Plastic Factories Are Doing to Fix Them

A Few Extra Pointers

- Insulate your piping to prevent heat gain between chillers and machines.

- Track ambient temperatures in the factory & dynamically adjust cooling.

- Reuse waste heat from compressors or chillers in other parts of the process.

- Stagger high-heat operations throughout the day to avoid peak load spikes.

Final Thoughts

Cooling is the quiet workhorse of any plastic factory. It protects your equipment, ensures consistent product quality, & keeps energy costs under control. When cooling systems are designed & maintained correctly, production runs more smoothly, downtime decreases, & output remains reliable. For plastic manufacturing facilities across the UAE, Presto Electromechanical LLC gives robust, energy-efficient process cooling systems tailored to factory needs — helping businesses stay productive, stable, & cost-efficient year-round.