Cooling Tower Services in UAE

Process Cooling for Plastic Factories & Cooling Systems for Plastic Manufacturing – By PRESTO

Introduction: Optimize Your Plastic Manufacturing with Reliable Process Cooling Solutions

In the highly demanding world of plastic manufacturing, temperature control is not just a preference—it’s a necessity. Whether you’re molding, extruding, or thermoforming, maintaining the proper cooling temperature is crucial for ensuring product quality, reducing cycle time, and improving overall efficiency. At PRESTO, we specialize in advanced process cooling systems for plastic factories, designed to support precision, performance, and energy efficiency across your production line.

With 40 years of engineering experience and tailored solutions for diverse plastic applications, PRESTO delivers cooling technologies that help plastic manufacturers stay competitive, reduce operational costs, and ensure product consistency.

Why Process Cooling Is Critical in Plastic Manufacturing

Plastic manufacturing involves high-temperature operations, including injection molding, blow molding, and extrusion. Here’s why efficient cooling is vital:

- Reduces Cycle Time: Faster cooling translates to quicker production cycles, improving output without compromising quality.

- Ensures Dimensional Stability: Proper cooling avoids warping, shrinkage, and other deformations, ensuring that each product meets dimensional standards.

- Prevents Equipment Overheating: Continuous operation of molding machines can cause overheating. Cooling systems safeguard both machines and molds.

- Improves Product Quality: Consistent temperature control eliminates surface defects and ensures homogeneous structure in the final plastic components.

At PRESTO, we help you maintain the optimal temperature during and after processing, ensuring smooth operations at every stage.

Our Process Cooling Solutions for Plastic Factories

PRESTO offers a comprehensive portfolio of cooling systems tailored to the specific needs of plastic production. Our solutions include:

Centralized Chiller Systems

Ideal for large-scale plastic factories, centralized chillers provide a consistent cooling source to multiple machines through a closed-loop system. Benefits include:

- Greater efficiency and uniform cooling

- Lower maintenance

- Energy savings through VFD

Portable Water Chillers

For smaller or more flexible operations, portable chillers are perfect. These are easy to relocate and ideal for short production runs or as a backup cooling system.

- Quick installation

- Compact and modular

- Ideal for injection molding and extrusion machines

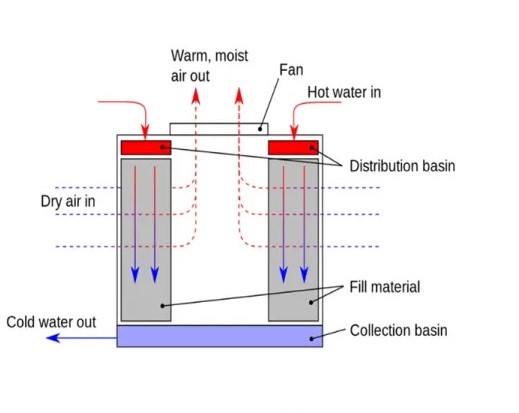

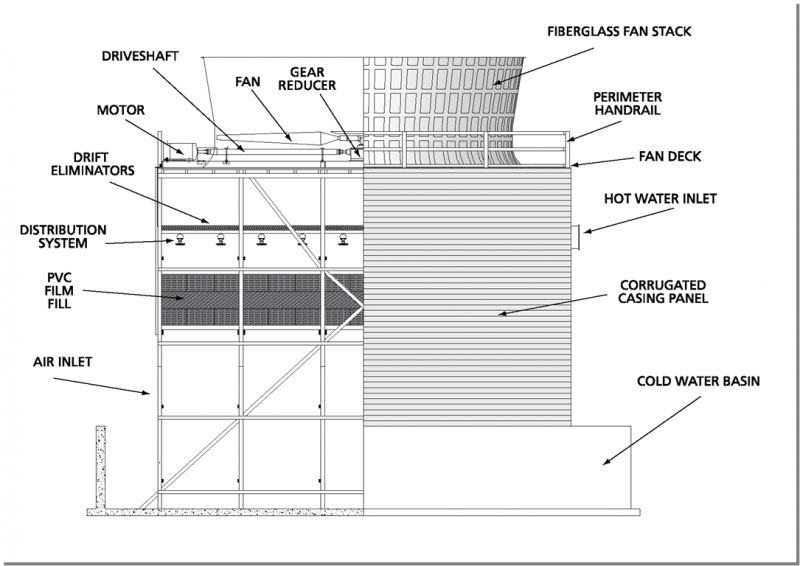

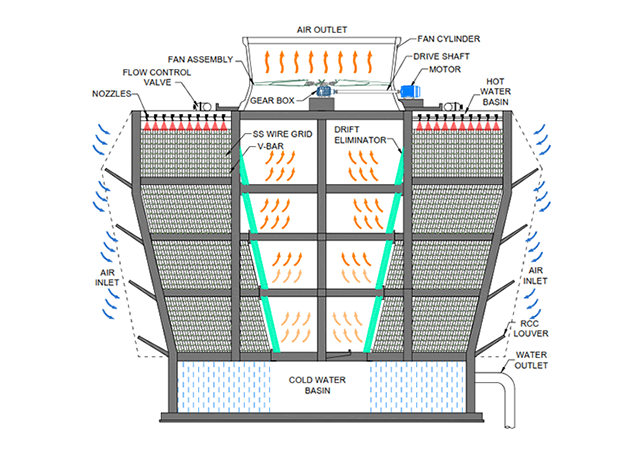

Cooling Towers

Our industrial cooling towers are designed for high-volume cooling and are especially suitable for large extrusion lines and recycling operations.

- High-capacity performance

- Long service life

- Water conservation and optimized airflow

Mold Temperature Controllers (MTC)

PRESTO offers intelligent MTCs that maintain mold temperature within a precise range, ensuring consistency and faster molding.

- Enhanced product quality

- Less scrap generation

- Quick mold warm-up and consistent cycle times

Custom-Built Process Cooling Systems

We understand that every plastic production line has unique requirements. Our custom cooling systems are designed specifically for your application, whether you’re working with PVC, HDPE, PET, or other polymers.

- Tailored designs to meet plant layout and capacity

- Integration with existing control systems

- Optimized for energy efficiency and automation

Applications of Our Cooling Systems in Plastic Manufacturing

PRESTO’s cooling systems are used across a wide range of plastic processes, including:

- Injection Molding: Fast cycle cooling for precision-molded parts

- Blow Molding: Neck and body cooling for consistent bottle production

- Extrusion: Die and barrel cooling for continuous extrusion lines

- Thermoforming: Mold cooling for shaping heated plastic sheets

Plastic Recycling: Granulator and equipment cooling to handle heat loads

Key Features of PRESTO Cooling Systems

What makes PRESTO stand out in the cooling systems industry?

- Energy-Efficient Operation: Our chillers and cooling towers are designed to minimize power consumption, ensuring optimal energy efficiency.

- Smart Temperature Control: Digital controllers ensure precise thermal regulation.

- Modular and Scalable: Our systems grow with your plant’s production capacity.

- Durable Build Quality: Made from corrosion-resistant materials suitable for industrial environments.

- 24/7 Technical Support: Ongoing service, support, and maintenance from PRESTO professionals.

Why Choose PRESTO for Your Plastic Factory Cooling Needs?

PRESTO has established a reputation for delivering cutting-edge cooling solutions across various manufacturing sectors, particularly in the plastics industry. Here’s what you get when you partner with us:

- Customized engineering and on-site consultation

- Energy-saving system design and ROI-focused planning

- Quick installation and commissioning

- Reliable after-sales support and AMC options

Our goal is to help plastic factories across the region operate with reduced downtime, consistent quality, and lower energy bills.